As a family-owned business for more than a century, Deister Machine Company, Inc., plays an integral part within the aggregate industry. Many of the world’s largest producers prefer its high quality line of feeding, scalping and screening equipment. Deister is also actively involved in the mining, coal, recycling and other industries requiring its products

As a family-owned business for more than a century, Deister Machine Company, Inc., plays an integral part within the aggregate industry. Many of the world’s largest producers prefer its high quality line of feeding, scalping and screening equipment. Deister is also actively involved in the mining, coal, recycling and other industries requiring its products

One of the few companies left in the industry to resist conglomerate buyouts or foreign investors, Deister Machine Company, Inc. is rich in a history that began prior to World War I and continues into the new millennium, still guided by a family management that professes old-world traditions of workmanship, dedication to its employees, technological advancement and a solid business philosophy of putting the customer first. Each piece of equipment is designed and customized to meet specific customer needs, an aspect that is critical to the cost-efficient processing of varying materials within the aggregate and mining industries.

From its first year in operation to the present, Deister Machine Company remains a proud contributor to the local, state and national economy. In 1912, the company employed 24 laborers. Currently, it supports more than 280 skilled employees. And, each year, Deister donates five percent of its income to charitable, cultural and religious organizations.

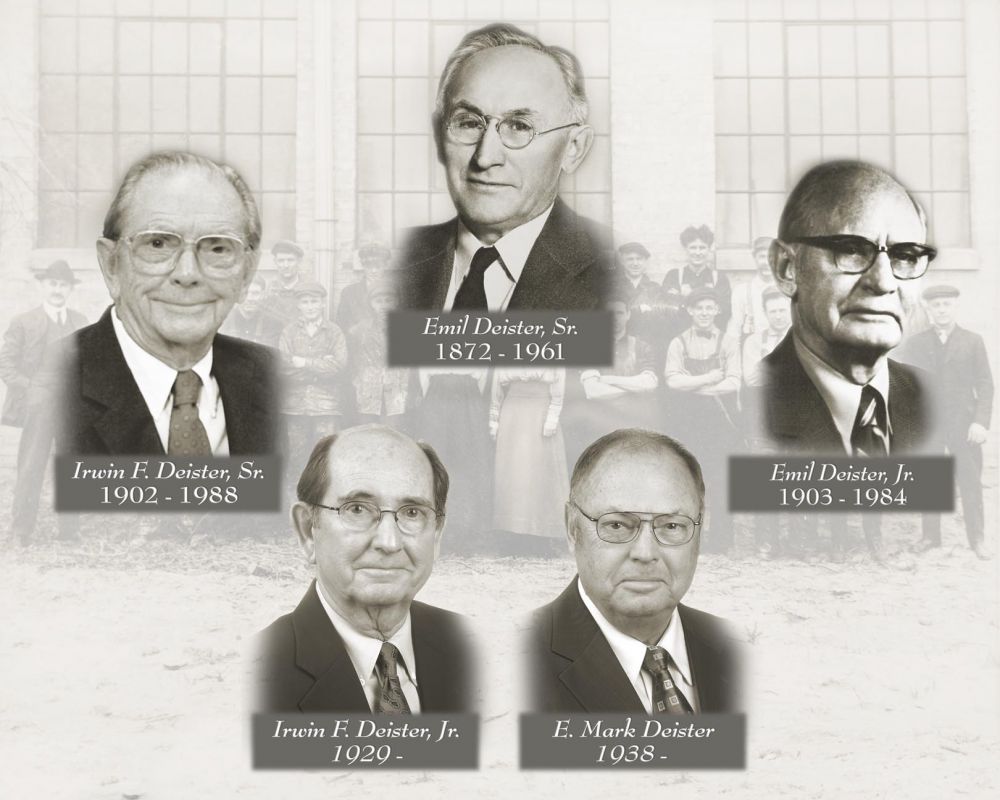

Irwin F. Deister, Jr., Chairman, and E. Mark Deister, President, represent the family’s third generation at the company’s helm. Irwin and Mark act as co-chief executive officers, each owning 50 percent of the shares, and together forming the board of directors. Their coveted tradition of quality and customer satisfaction began with their grandfather, Emil Deister, the company’s founder.

Born in Germany in 1872, Emil Deister moved to the United States where he settled with his parents in Woodburn, Indiana. In 1893, at the age of 21, he began his career as a lathe operator. Eventually, Emil took up the study of ore separation. He would patent his own equipment, starting with a centrifugal separator that extracted gold from mercury amalgam, and continuing on to develop ore-separating tables.

Born in Germany in 1872, Emil Deister moved to the United States where he settled with his parents in Woodburn, Indiana. In 1893, at the age of 21, he began his career as a lathe operator. Eventually, Emil took up the study of ore separation. He would patent his own equipment, starting with a centrifugal separator that extracted gold from mercury amalgam, and continuing on to develop ore-separating tables.

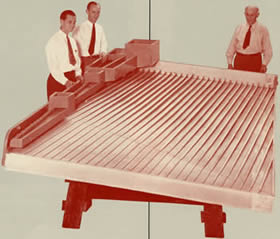

He built his first separating table in his basement. This differential-motion ore-separating table had riffles attached to its surface. The riffles collected the heavier ore particles and conveyed them in one direction toward a collector, while water washing across them carried the lighter impurities away.

The table is praised in Taggert’s Handbook of Ore Dressing, the official textbook at many mining schools, as the first serious competition to the only other kind of ore separating table available at the time.

Emil Deister set up business in 1906 as the Deister Concentrator Company. In 1912, Emil sold his interests in Deister Concentrator Company and established Deister Machine Company.

The company began manufacturing operations at 1933 East Wayne Street in Fort Wayne, its current location. The original building, a 5,500 square-foot plant, is still in active use amidst a total operation that today spans more than 460,000 square feet.

In 1926, upon customer request, Deister Machine Company began manufacturing vibrating screens for the separation of materials according to particle size, a process needed to meet state, federal, and industrial specifications.

In 1933, Deister introduced a special screen for sizing the aggregate used in hot-mix asphalt plants. Subsequently, the company added vibrating feeders, a wide variety of inclined and horizontal, and foundry equipment, including shakeouts, compaction tables, reclaimers.

.gif) Today, Deister Machine Company, Inc. focuses entirely on its core business, providing feeding, scalping and screening equipment to the aggregate and mining industry. This equipment is used throughout North America, and in many countries throughout Latin America, Europe, Australia, and Asia.

Today, Deister Machine Company, Inc. focuses entirely on its core business, providing feeding, scalping and screening equipment to the aggregate and mining industry. This equipment is used throughout North America, and in many countries throughout Latin America, Europe, Australia, and Asia.

Deister’s reputation has attracted customers known as the biggest aggregate producers in the business – corporations such as Martin Marietta Materials, Vulcan Materials, Lehigh Hanson, Lafarge, CRH Materials, LafargeHolcim, Cemex, Rogers Group, I. M. I. and others. Many of these top producers purchase Deister equipment exclusively and in volume. For example, Deister’s largest customer has more than 1480 Deister units amongst all its operations.

These customer relationships, developed over years of intense support, consultation and service have resulted in ongoing improvements in the design, engineering and customization of Deister feeding and screening equipment – never more important in an era when material specifications are tightening and producers are searching for the means to remain profitable in an increasingly competitive business environment.

Deister Machine Company, Inc., supports the industry by being active participants in a variety of key organizations. Irwin F. Deister, Jr., is a past chairman of the Manufacturers and Services Division of the National Stone Association (NSA), while E. Mark Deister served as chairman of the National Aggregates Association (NAA) Manufacturing and Services Division.

Today, both are life members of the board for the National Stone, Sand & Gravel Association (NSSGA). Rich Deister, Executive Vice-President, and Joe Schlabach, Vice-President of Marketing and Sales, are both past chairman of the NSSGA Manufacturing and Services Division, and Rich Deister is currently serving on its Executive Committee.

For Deister Machine Company, Inc., quality is its history. Its products are designed to integrate with all components of the production system, while delivering maximum performance and productivity. In fact, some of the earlier models of Deister vibrating screens are still in operation due to their rugged construction and continued high efficiency.